Vertex Hydropore specialises in the design and manufacture of skid mounted Reverse Osmosis (RO) plant across a wide range of commercial and industrial applications. Our range of skid mounted RO systems start with a production rate as low as 50 litres per hour right up to volumes of 50,000 litres per hour or larger, with a large selection of sizes in between.

Skid Mounted Reverse Osmosis Plant

Reverse Osmosis System Design

Reverse Osmosis systems consist of a number of different components depending on the quality of the feed water and the desired product water and we break these components down into the following categories:

Pre-Treatment

Reverse Osmosis Skid

Post-Treatment

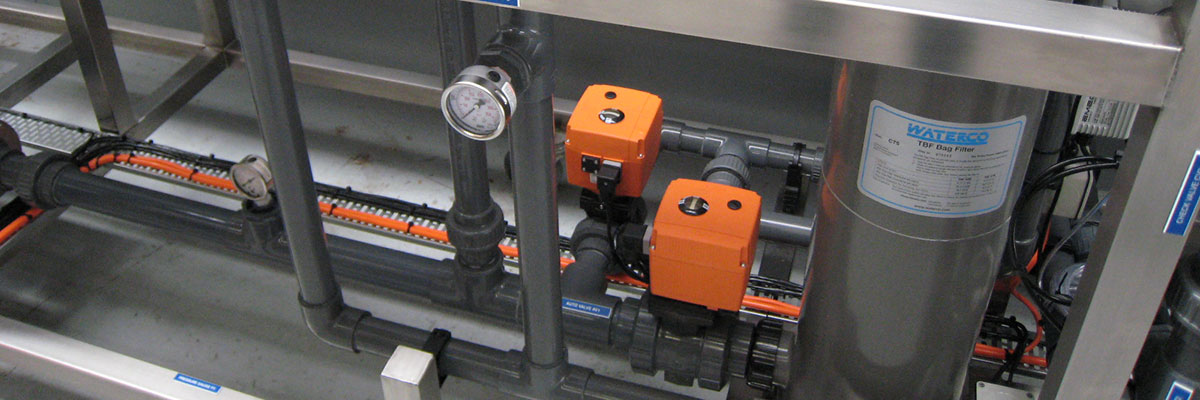

Reverse Osmosis Pre-treatment

The type of feed water introduced to the RO plant will determine the nature of pre-treatment selected. Please refer to our “Water Treatment Guide” for a full list of feed waters and their recommended RO system components.

One of the common water contaminants addressed by the pre-treatment stage is suspended solids. Fine particles of dirt and other matter floating in suspension within the feed water. These particles are not dissolved into the water and have to be physically removed via filtration.

Reverse Osmosis membranes, the core component of the RO plant are not designed to remove such suspended particles and will foul rapidly if left to do so. As such adequate filtration is required prior to any Reverse Osmosis System in order to achieve proper system operation and avoid premature fouling of the membranes.

Different feed waters will typically have different levels of suspended solids. Surface waters such as rivers and dams tend to have the highest levels, as they catch water running across the earth which is typically heavily laden with dirt and other solids. While bore water extracted from deep within the earth has much lower levels as the water has been filtered by the rocks through which it passes prior to collection. As such these two feed waters will typically require different pre-treatment technology. For example, it is considered best practice to operate an Ultrafiltration system prior to an RO plant for surface water, while bore water only requires the use of a media filter.

One of the first steps in designing a suitable skid mounted reverse osmosis plant therefore is collecting and analysing the proposed feed water. In doing so we will have a much better understanding of water to be purified. The information provided from the analysis can then be directly inputted into our design software, ensuring you get a robust, effective system that works first time with no surprises.

Reverse Osmosis Unit - Skid

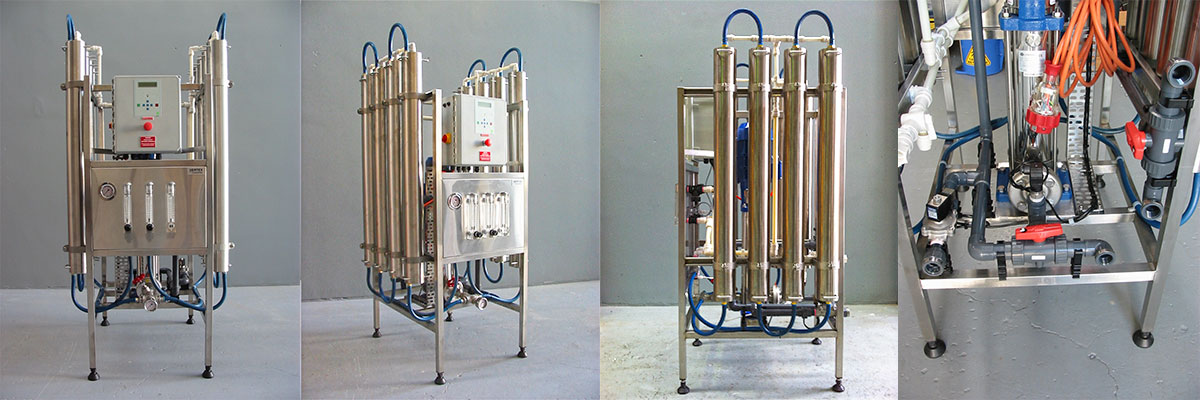

The RO unit itself will be designed and manufactured at our premise here in Sydney, Australia. We have a team of trained technicians who build, test, commission and maintain our RO plant nationally. We find this level of cross training highly effective at ensuring that our RO systems provide the highest levels of reliability and that any potential issues are identified early and resolved quickly.

All our skid mounted Reverse Osmosis systems feature:

- All stainless steel frames and wetted parts

- Quality label components such as Berkert, Grundfos, Lowara & Georg Fischer

- Skilled local assembly to Australia Standards

- Innovative designs that minimise floor space while maintaining ease of service

Our skid mounted RO plant utilise either 2.5”, 4.0” or 8.0” Filmtec or Hydranautics reverse osmosis membranes suitable for the application and we carry a full range of spares and consumables on site to ensure you’re never caught without water when you need it most.

Our RO plant are designed to maximise water efficiency and minimise waste. The recovery rate, that is the ratio of feedwater recovered as product can be as high as 80-85%. However this can drop down depending on the nature of the feed water. Too much salinity or silica amongst other things in the feed water will limit the recovery rate of the unit. Once we have the water analysis of your feed water we will be able to provide you with an accurate estimation of the final Reverse Osmosis system water recovery.

A typical RO skid will include only the components of the RO unit, whilst both the Pre and Post treatment elements will be separate, floor or wall mounted components that are plumbed together on site. This approach reduces the cost of the actual skid as the frame does not have to be as large. It is also easier for installing systems into pre-existing infrastructure as the individual components are easier to get through door ways.

In some cases however clients may be interested in having all the RO system components mounted and plumbed onto a single skid such as this duty standby unit. This has the advantage of a simpler installation as the unit is dropped on site, the water and power are connected and it is ready for operation. Having everything mounted onto a single skid greatly reduces the onsite time of technicians which can often offset the increased cost of the system. Speak to one of our system designers to find out which approach is best for you.

Post Treatment

Following the RO plant there are a number of options for tailoring the product water to different applications. Sterilisation, Remineralisation and Resin polishing are all examples of post RO plant processes that can be employed to make sure the system product water meets your specification.

It is quite common, but not necessary for the RO water to go through one of more post treatment processes prior to use and further information is available on this site. Sterilisation is one of the most commonly used types of post treatment.

Let Us Design Your Next Skid Mounted RO Plant

Once you’ve had a good look over our site and are ready to get started, or even if you simply have a few questions for which you are unsure, contact our friendly staff and have a chat. We’re always happy to help and can handle most Reverse Osmosis requirements and if we can’t we’ll point you in the right direction.